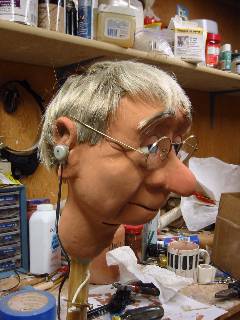

Today is busy, but there's not much to report in the way of progress. I'm doing a lot of sanding and fitting. The jaw fits and operates well now. There are, however, some issues to consider before I start assembling and painting.

The Complexion: Smooth or Rough?

Old men have rough complexions. Wrinkles, blemishes, pits, bumps, and so on. It would be easy to keep the natural roughness that results from a clay model, a plaster mold, and a fiberglass cast. I've seen many ventriloquist dummies with really bad complexions, and many of them aren't elderly characters. A stroll through Vent Haven shows what I mean. And some contemporary figure makers produce rough-looking dummies even today. The philosophy is, I suppose, why expend a lot of time perfecting what is, after all, only a puppet.

I built Aunt Sally in only a few days because I needed her for a performance. I took a lot of short cuts to meet the schedule. As a consequence, Aunt Sally was rough. The performance was onstage at a concert in a dark concert hall, and no one noticed. But I noticed. I'm the guy who has to stand next to her. So, the following week, I tore her down and gave her a facelift. Nobody else noticed, but it is important to me.

Here are before and after pictures. Click them to see the differences.

Look at some of the figures made by many prominent figures makers of yore. They are rough. They are cartoonish in appearance with rough surfaces and garish paint schemes. Then look at the original Charlie McCarthy in the Smithsonian. You can get up close to Charlie and take a good look. He is virtually flawless.

Get up close to Danny O'Day, which you can do at the annual convention. He is a work of art, well designed, well built and well maintained. Examine any Selberg figure in the dealers' rooms. Flawless. That's what the rest of us strive for.

When To Do What

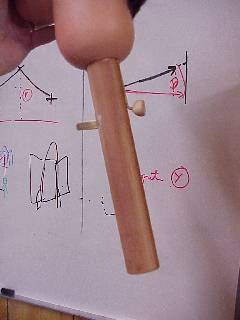

Making a figure is an engineering project. Things have to be done in their proper order. After making several figures you learn what ought to be done when. For example, don't install the eyes until you've painted around the eye holes. Don't install jaw until you've painted the tongue and teeth. Don't assemble the head with an unreachable and unfinished component way down in there someplace. I can't tell you how many times I've spent a day with needle nose pliers trying to loop the end of a spring onto a screw eye that I can't reach. Or a string through a pulley. Or how many times I've tried to thread a screw eye into a place way down in the neck because I forgot to install it when I could reach where it needs to be.

But some things defy careful planning. Uncle Sweeter's jaw is, of course on the front of his head. The place where the other end of the jaw spring attaches is on the back inside of his head. Installing a jaw spring involves trying various lengths until the tension is just right. The two halves need to be permanently attached to do that. With the two halves together it's difficult to reach the place where the spring attaches. And on and on.

Custom and Production Line Dummies

When you build custom dummies, you run into the issues discussed above and many others. But when your business is building and selling dummies from a product line of characters, it is foolish to make every project unique. You need to minimize the time you put into each dummy if you want to earn more than minimum wage. Which means you need a production line approach to building.

Look at Lovik dummies, particularly the ones Craig Lovik built toward the end of his career. They are nice figures, indeed, but they are characterized by a need to streamline production and minimize costs. The faces have smooth features with no undercuts. This approach makes molding and casting much easier. The jaws have wide slots. This approach minimizes the time needed to fit a jaw into a face. In fact, I've never seen a cast Lovik head that had a well-fitted jaw. One of the features that surprised me had to do with the size of the dummy. I forget the details, but for extra money, you got a larger dummy. Maybe 42 inches instead of 38. Based on two figures I had in my shop, the only difference was that the stuffed legs were longer on the larger dummies. Everything else was the same.

Uncle Sweeter is a one-of-a-kind figure, which is all I make these days. I will take the time to make everything as perfect as I can. I'm in no hurry. In fact, if I was under pressure to complete him by a deadline, I wouldn't spending all this time taking pictures and posting project status on this blog.

But that would take all the fun out of it.